CyXplus supplies its CyXCT+series range of equipment featuring CyXray 2D X-ray exploitation software, and CyXCT 3D Computed Tomography reconstruction software. Using validated technology building blocks, CyXCT+series machines are suitable for the inspection needs of small and medium size parts for Aerospace and Defense Industries, as well as all kinds of manufacturing fields such as Automotive, Medtech, etc...

Taking benefit of its large experience as an integrator, CyXplus is proud to present its CyXCT+series :

Digital radiography advantages

Easy to use : real time visualization

Environmental respect : no chemistry for development

Easy storage, exploitation and use of data

Meet your industrial requirements :

Quality : software meeting standards in use (ASTM E 2737, ISO 17636-2)

Efficiency : Definition of acquisition cycles

Reliability : Automatic sequence of periodic performances process control

User friendly : intuitive and tactile 19’’ interface

Detection assistance thanks to filters and image processing

Customize the system to your particular needs

X-ray chain can be changed for better resolution / process cycle time

Large loading volume with turntable and various part flanges

Easy access to equipment

CyXCT+series is a complete range of X-ray/CT equipment from 160kV to 450kV. CyXCT machines are designed to offer versatile characteritics in terms of inspection (X-ray and/or Computed Tomography), macrofocus or microfocus sources, and to embed various flat panel detectors of various sizes and resolution.

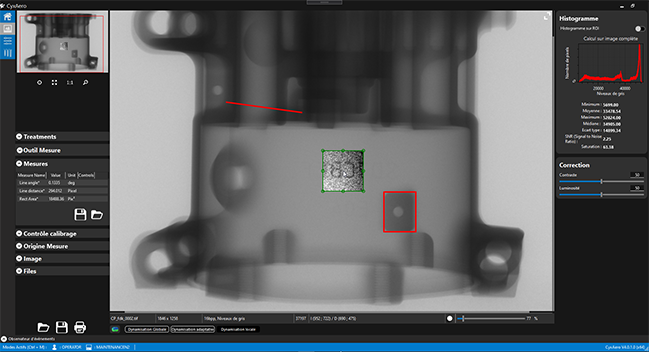

CyXray is a powerful and ergonomic 2D X-ray acquisition and visualization software.

Detector management in background upon PLC order

Acquisition, offset, gain, bad pixels correction

Software or hardware correction of gain/offset/bad pixels

Multi-mode acquisition (simple, integrated, sequence..)

Actions when ending acquisition (flip, display of saturation level, image back-up, transfer to another software…)

Bad pixels management (display of the mapping, classification, display on the image)

Automatic procedure for performance monitoring based on ASTM E-2737 standard (View of duplex IQI profile, grayscale, duplex plate phantom measurement, lag, burn-in, offset level)

Image processing & visualization

Brightness, contrast, customized LUT

Local, adaptive or global dynamic filter

Display resolution choice

Local or global histogram

Crop, zoom, pan

Real Image Viewer for image processing

Import data: marked standard professional file formats

Export data: HR imaging in multiple image formats, TIFF, JPEG DICONDE (.DCM)

Normative tools

User identification, pixel map; SNR & CNR Measurement, comparison with reference images (ASTM), in compliance with ISO 17636-2, ASTM-E2698, E2736,E2737,E2597,E2422,E2660,E2669,E2869.

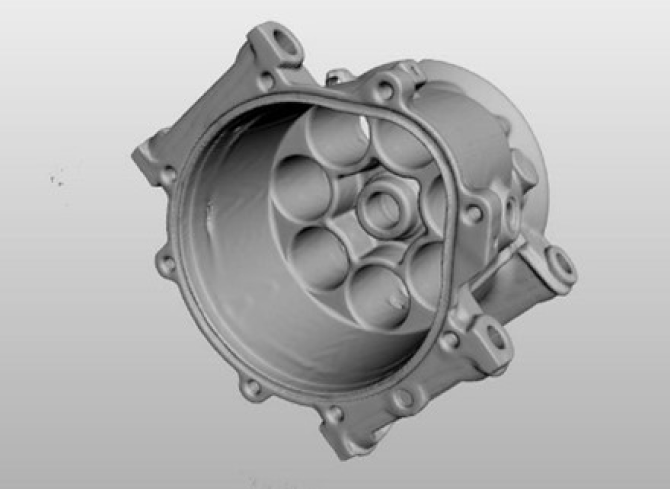

CyXCT is a powerful and user-friendly Computed Tomography software embedding calibration, reconstruction and visualization modules.

Analytical & Iterative reconstruction algorithms

> 64 bits, no data size limit at input

> Iterative algorithms for superior image quality and reduction of acquisitions (e.g. for in-process inspection)

High-resolution, real-time volume and surface rendering

> Orthogonal or user-specific cut planes

> Advanced segmentation & voxel measurement (points, segments, angles, circles)

> Post-process data in 3D: metal artifact reduction

> Certified mesh export (triangles with perfect shapes, no missing ones) in SURF, STL, POINTS and OBJ

Certified calibration tool tailored for reconstruction parameters acquisition

> Real Image Viewer for image processing

> Sophisticated software feature for multi-GPUs acceleration

> Import data: all well-renowned professional file formats

> Export data: HR slices in multiple image formats, DICOM, video…

Surface extraction and simplification

> Compliant with expert metrology software and 3D CAD Comparison

Meet your industrial requirements :