CyXplus supplies tire manufacturers with solutions from fully automated implementations to off-line analysis using X-ray, Industrial Vision, Image Processing and AI, and covers the needs for motorcycle, passenger, Truck-and-Bus and Off-the-Road (up to the largest) tires.

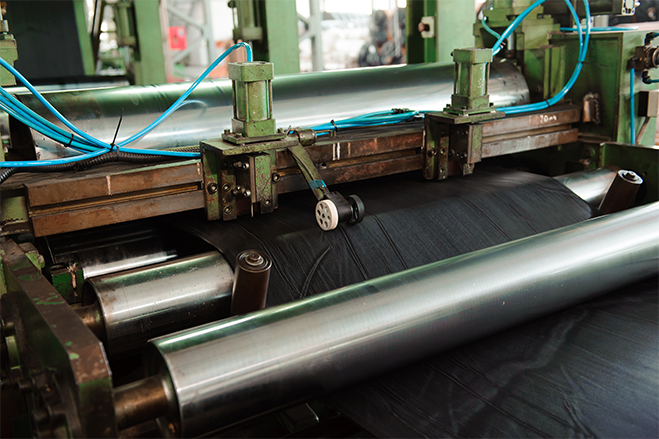

CyXplus developed a unique solution for controlling the body ply belt prior to tire assembly. This solution allows manufacturers to adjust their belt manufacturing process and save raw material and energy on tire manufacturing lines.

CyXbelt has been specifically designed to inspect metallic corded belt plies, and measure distance, thickness, orientation of metallic cord. Foreign material and air traps will also be detected in parrallel with geometry inspection. The marking option will allow to visually identify which part of the belt is defective according to quality criterias, and will enable operator to remove the specific part for the next step of manufacturing.

PCR12-25 and TBR15-27: X-ray inspection of PCR (12-25" ID) and TBR (15-27" ID) tires.

The PCR12-25 and TBR15-27 machines favor horizontal handling of the tire throughout the process.

This design allows to:

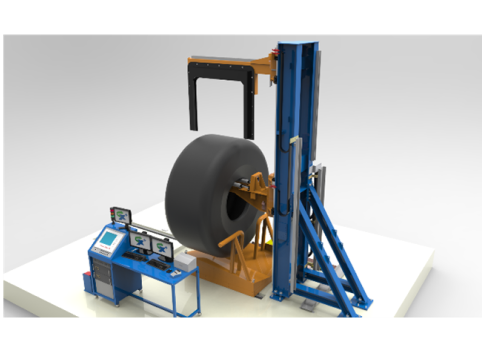

OTRX range: from 20''ID OTR to 63''ID Earth-Mover tires, the OTRX range of machines is a unique offer for Off-The-Road tire X-ray inspection, with wide possibilities in dimensions, high image quality, automated cycle and optimized cycle time.

CyXmark will allow manufacturers to inspect all marking areas and quality as regulatory marking, commercial marking or production marking, which can be done by OCR, pattern match or logo identification.

CyXplus provides a complete range of inspection machines for radial tires, boosted by CyXpert (X-ray inspection software), the reference ADR software in the Tire Industry. These Tire inspection solutions are designed to check the internal structure of the tire (X-ray), and to check the external quality focus on marking quality (Vision). All our solutions are improved by our recent developments in AI.

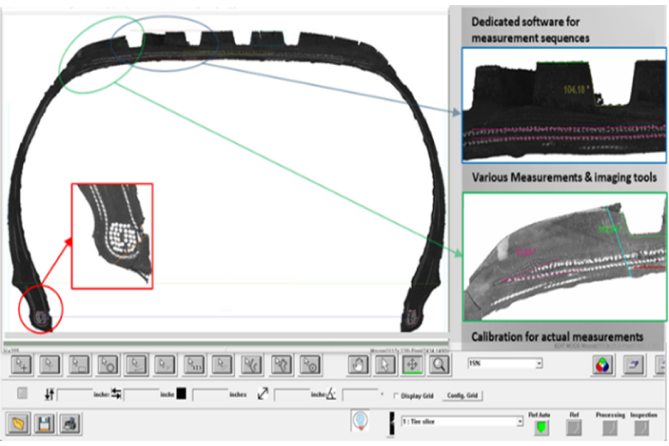

CyXscan

Cross Section Scanning System

The purpose of the CyXscan system is to allow the Engineering or the Q.A. Department to check tire cross sections that are cut every day in sampling coming from the production line, and to carry out millimetric measurements:

The equipment is composed of:

CyXplus supplies the most Tire industry-dedicated tool to control and perform measurements on tire cross sections.